12 What is an Electrostatic Precipitator. 0 0 0.

Electrostatic Precipitator For Fine And Ultrafine Particle Removal From Indoor Air Environments Sciencedirect

The intensity of electrostatic field at which the corona discharge occurs is called critical and can be calculated with the formula 1.

. Efficiency of Electrostatic Precipitator. An electrostatic precipitator ESP is a large industrial emission-control unit. Leading brand of electrostatic precipitator for commercial kitchen ventilation.

The user-friendly interface of the. Particle drift velocity V d 0. Figure 31 is an example of electrostatic precipitator components.

Dust particles are removed from a gas stream in electrostatic precipitators due to the action of electrostatic forces. Solution The process of electrostatic precipitation consists of corona formation around a hightension wire with particle charging by ionized gas molecules formed in the localized region. 0298 303 1 r E ρ ρ 1.

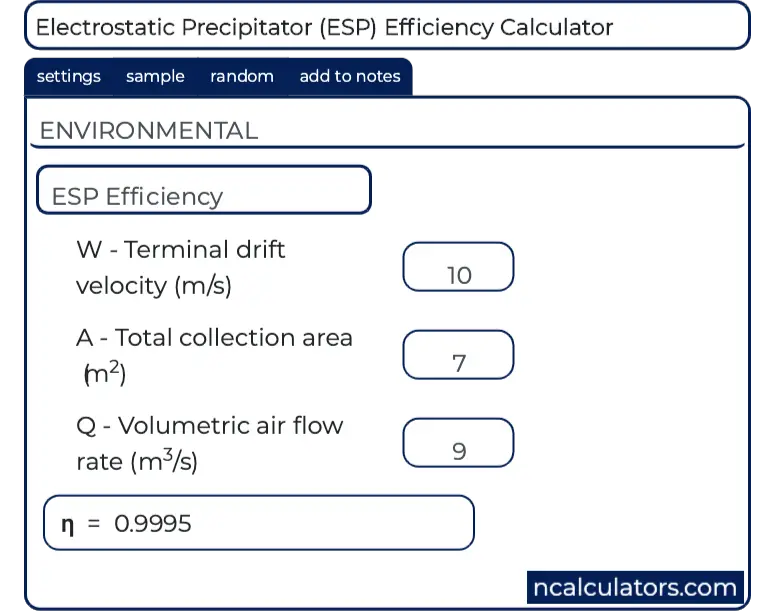

E elementary charge electric charge carried by a single proton or the negation of the electric charge carried by a single electron 16 x 10-19 C Q flow rate 73m3 s V 𝐼 𝐴𝑒. Electrostatic PrecipitatorESPs Efficiency Formulas. Begin array leta 1-e frac -WA Qend array where 𝜼 is the fractional collection efficiency.

C Indian Academy of Sciences Numerical calculation of particle collection efficiency in an electrostatic precipitator NARENDRA GAJBHIYE1 V ESWARAN2 AKSAHA1 and ANOOP KUMAR3 1Department of Mechanical Engineering IIT Kanpur Kanpur 208016 India 2Department of Mechanical and Aerospace. Introduction Electrostatic precipitator ESP is a highly efficient device for cleaning exhaust gases from industrial processes. 40 Part 3 May 2015 pp.

ESPs this design operates equally well with either negative or positive polari-ty. The first is that. Also use the modified Deutsch equation with a range of exponents varying from 04 to 07 in increments of 005 to calculate the efficiency of the electrostatic precipitator.

The efficiency of the electrostatic precipitator is dependent on the particle size of the aerosol dust mist to be collectedThe collection efficiency if high for more massive particles and low for small particlesThe formula to calculate the efficiency. This model to the first of the three steps of electrostatic. The simplest form of the equation is given below.

1 shows a photograph of electrostatic precipitator ESP for. This is usually accomplished by knocking them. Between a positive and a negative electrode an electric field is established in which the charged dust particles are forced to move in the direction of the collecting electrode on the surface of which a very porous layer of dust builds up with time.

ARCADIS Geraghty Miller 4915 Prospectus Drive Suite F Durham NC27713 EPA Contract No. Design procedure Draft design based on. The use of the plant parameters to test operator or maintenance actions.

Electrostatic precipitator design calculation Mention a fresh new and vibrant design. Electrostatic precipitator calculator solving for collection efficiency estimate given electrodes collecting area gas flow rate and particle drift velocity Electrostatic Precipitator Design Equations Formulas Calculator - Collection Efficiency Estimate. Kenneth Parker and Norman Plaks Under subcontract to.

A is the total collection area in m 2. The calculation velocity for rapid what - if answers. Electrodes collecting area A meter2 particle drift velocity V metersecond gas flow rate Q meter3second.

2ris016 ElctrostateProcptator Design Equations Formulas Calculator - Colloct Electrostatic Precipitator Design Calculator Air Pollution Control Solving for collection efficiency estimate oa Reivel Inputs. A total area of the collecting surface of the collection electrodes m 2 Q flow rate of gas through the. Therefore new precipitator designs may be based on gas flow figures which are too low by 10 or more unless adequate allowances are made.

----- EPA-600R-04072 July 2004 Electrostatic Precipitator ESP Training Manual Prepared by. Osition of a lateral electrostatic force on the particle and its. η collection efficiency of the precipitator e base of natural logarithm 2718 w migration velocity cms ftsec A the effective collecting plate area of the precipitator m2 ft2.

Collision in the case of capture with the collection plate 2 the retainment of the particle on the plate and 3 the. The calculation of the parameters of the electrostatic precipitator starts with the selection of the corona discharge Fig. Once the particles are collected on the plates they must be removed from the plates without reentraining them into the gas stream.

General specification analysis expected exhaust particle concentration site specific physical constraints previous similar projects Simulation and optimisation of the gas flow in the ESP body adoption of smoothing profiles at the inlet and exit Simulation of the particle capture. η 1 - e -WA Q Where. It is designed to trap and remove dust particles from the exhaust gas stream of an industrial process by using the force of an electric field.

V 006 𝐴 61016 337 2161019𝐶 168 ms Collection efficiency. The obtained results showed that the adopted design of the electrostatic precipitator enables the reduction of dust emissions generated in the combustion of solid fuels in households at relatively. Decorative range hoods Details about electrostatic precipitator design calculation island mount range hood on Ruizhaohe Certificate.

W is the terminal drift velocity in ms -1. The main expectations of future users regarding that tool are related to. A flat plate ESP operates with little or no corona current flowing through the collected dust except directly un-der the corona needles or wires.

Srivastava National Risk Management Research Laboratory. The possibility of verifying changes in the design of the electrostatic precipitator. At high voltage in the center of the flow lane.

The manufacturer has chosen to use positive polarity to reduce ozone gener-ation. Used to determine the collection efficiency of the precipitator under ideal conditions. 68-C-99-201 Work Assignment 4-30 EPA Project Officer.

This nail artwork injects an exciting temperament in you. Because precipitator performance data banks are as a rule based on pitot tube measure ments whereas gas flow specifications for new precipitators commonly are calculated using the balance methods. This has two consequences.

A 37 m2. We need Electrostatic Precipitator in order to reduce pollutants emitted into the atmosphere. These three steps are.

Q is the volumetric air flow rate in m 3 s -1. The collection efficiency of an electrostatic precipitator may be estimated by an empirical equation. 2014 R 1 exp A v d Q where.

Design Efficiency of ESP Maria J drusik and Arkadiusz wierczok Wroclaw University of Technology Poland 1. With the light pinkish and white shades mixed with the seemingly washed on peach colored petals displays as In the event the Solar has picked to shine on you and only you. Electrodes collecting area A 0.

Schematic Diagram Of A Wire Plate Electrostatic Precipitator Download Scientific Diagram

Electrostatic Precipitator Design

Electrostatic Precipitator Efficiency Calculator

Electrostatic Precipitator Ppt Video Online Download

Scielo Brasil Evaluation Of The Performance Of A Wire Plate Electrostatic Precipitator Evaluation Of The Performance Of A Wire Plate Electrostatic Precipitator

Electrostatic Precipitator Efficiency Calculator

Electrostatic Precipitator Design

Pdf Numerical Calculation Of Particle Collection Efficiency In An Electrostatic Precipitator Semantic Scholar

0 comments

Post a Comment